Understanding polarity in electronic circuits is fundamental for anyone beginning their journey in electronics, as incorrect orientation can damage components or prevent circuits from functioning entirely.

🔌 The Foundation of Electrical Polarity

Polarity represents one of the most critical concepts in electronics, referring to the distinction between positive and negative electrical charges. In basic terms, polarity defines the direction of current flow and voltage difference in a circuit. For beginners, mastering this concept early prevents countless frustrating troubleshooting sessions and component failures.

Every electronic component interacts with electrical current in specific ways, and many components are polarized, meaning they must be connected in a particular orientation to function correctly. Understanding which components require polarity awareness and which don’t forms the cornerstone of successful circuit building.

The concept of polarity extends beyond simple positive and negative terminals. It encompasses understanding electron flow, conventional current direction, and how different components respond to electrical potential differences. This knowledge becomes particularly important when working with direct current (DC) circuits, where polarity remains constant, unlike alternating current (AC) systems.

⚡ Identifying Polarized Components

Not all electronic components care about polarity, but many critical ones do. Recognizing which components require correct orientation saves both time and money by preventing component damage and circuit malfunction.

Capacitors and Their Polarity Requirements

Electrolytic capacitors represent one of the most commonly used polarized components in beginner circuits. These cylindrical components typically feature clear markings indicating their negative terminal, often with a stripe containing minus symbols or arrows. Ceramic and film capacitors, conversely, are non-polarized and can be installed in either direction.

Installing an electrolytic capacitor backward can result in catastrophic failure, including leakage, overheating, or even explosion. The negative leg is usually shorter, and the body often has a clear band marking the negative side. Modern surface-mount capacitors also include polarity markings, though they may be smaller and require careful inspection.

Diodes: The One-Way Valves of Electronics

Diodes function as electrical check valves, allowing current to flow in only one direction. The cathode (negative) end is typically marked with a band or stripe, while the anode (positive) end remains unmarked. Light-emitting diodes (LEDs) follow similar principles but add the complication of requiring current-limiting resistors.

LEDs typically have a longer positive lead (anode) and a shorter negative lead (cathode). Additionally, looking inside a transparent LED reveals a smaller element connected to the cathode and a larger cup-shaped element connected to the anode. Reverse-connecting an LED won’t usually damage it immediately, but it simply won’t illuminate.

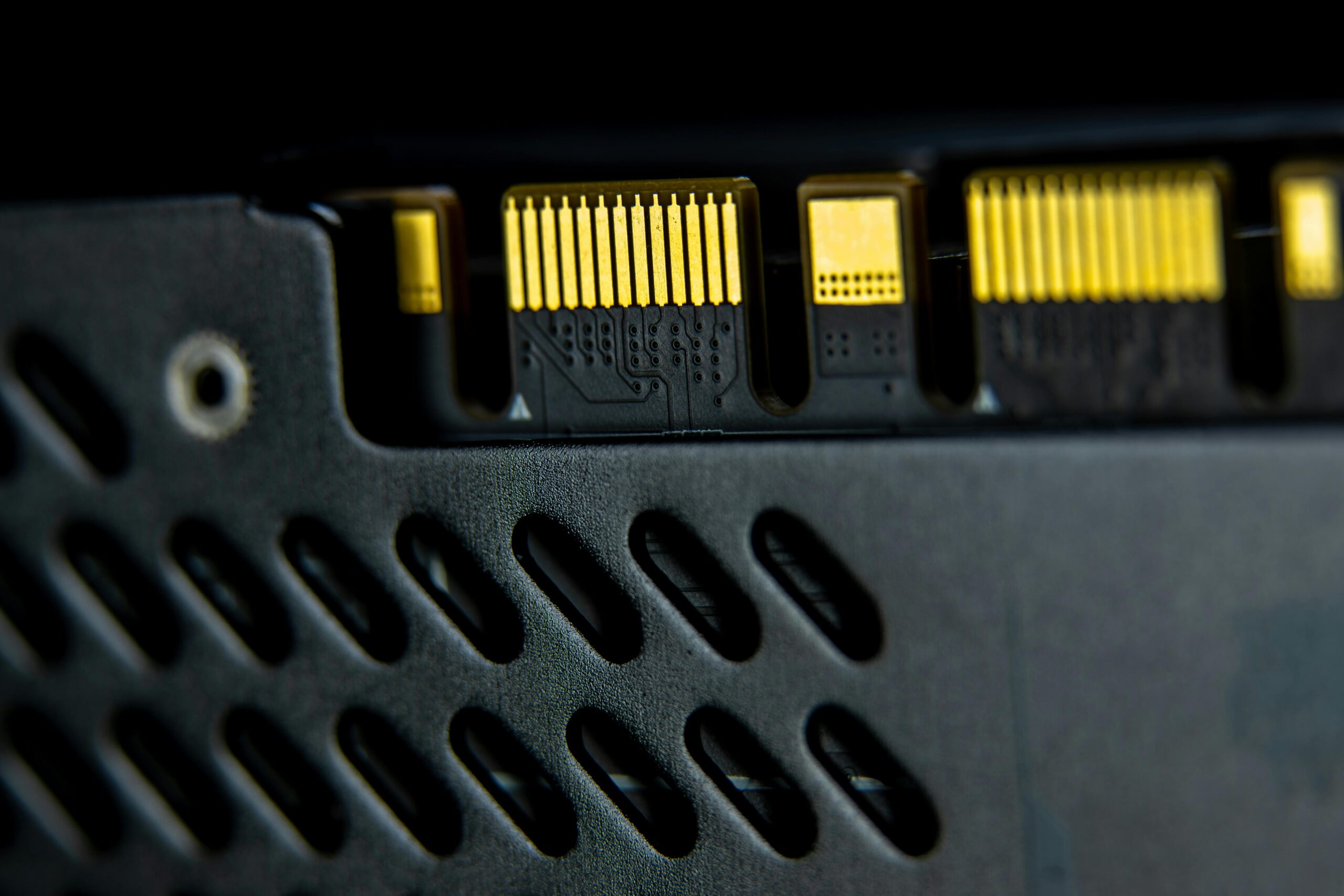

Integrated Circuits and Proper Orientation

Integrated circuits (ICs) require precise orientation for proper functionality. Most ICs feature a notch or dot indicating pin one, from which numbering proceeds counterclockwise when viewed from above. Inserting an IC backward almost certainly damages it permanently, making careful orientation verification essential before applying power.

🔋 Power Supply Polarity Fundamentals

The power supply represents the heart of any electronic circuit, and understanding its polarity configuration proves essential for circuit success. Most beginner projects utilize DC power supplies, whether from batteries, wall adapters, or bench power supplies.

Battery holders and connectors follow standardized color coding in many regions, with red indicating positive and black indicating negative. However, never rely solely on color coding—always verify polarity with a multimeter before connecting components. Some imported or custom components may not follow these conventions.

Wall adapters and external power supplies should always specify their output polarity, typically shown with a diagram indicating whether the center pin is positive or negative. This designation is crucial because different devices use different standards, and connecting the wrong polarity adapter can destroy your circuit instantly.

Creating Polarity Protection in Your Circuits

Smart circuit design incorporates polarity protection mechanisms to prevent damage from accidental reverse connection. A simple series diode provides basic protection by blocking reverse current, though this approach introduces a small voltage drop. More sophisticated circuits use P-channel MOSFETs or dedicated protection ICs for reverse polarity protection without significant voltage loss.

For beginners, adding a protective diode in series with the positive power input offers inexpensive insurance against mistakes. Choose a diode rated for higher current than your circuit draws to minimize voltage drop and heat generation.

📐 Practical Polarity Verification Techniques

Before powering any circuit, methodical polarity verification prevents component damage and ensures optimal performance. Developing these habits early establishes good practices that benefit you throughout your electronics journey.

Using a Multimeter for Polarity Testing

The digital multimeter serves as the essential tool for polarity verification. Set your meter to DC voltage mode and measure your power supply output. The display will show a positive value when the red probe touches the positive terminal and the black probe touches the negative terminal. A negative reading indicates reversed probe placement or reversed supply polarity.

When testing components like electrolytic capacitors, the diode test mode on your multimeter can verify polarity by showing the forward voltage drop in one direction and no reading in the reverse direction. This technique works excellently for diodes and transistors as well.

Visual Inspection Best Practices

Develop systematic visual inspection habits before applying power to any circuit. Check every polarized component individually, verifying its orientation against your schematic or reference documentation. Use good lighting and magnification when needed, especially for surface-mount components or densely populated boards.

Create a checklist approach: first verify power supply connections, then check all electrolytic capacitors, followed by diodes and LEDs, then ICs, and finally transistors. This systematic method ensures nothing gets overlooked in the excitement of completing your build.

🛠️ Common Polarity Mistakes and Solutions

Even experienced electronics enthusiasts occasionally make polarity errors, but beginners are particularly vulnerable to certain common mistakes. Understanding these pitfalls helps you avoid them and troubleshoot more effectively when problems arise.

Schematic Reading Errors

Misinterpreting schematic symbols represents a frequent source of polarity errors. Capacitor symbols show polarity with a curved line (negative) and a straight line (positive), while diode symbols use a triangle pointing toward the cathode with a bar representing the cathode itself. Taking time to learn standard schematic symbols thoroughly prevents many assembly mistakes.

Some schematics use different conventions or simplified symbols that may confuse beginners. When uncertain, research the specific component datasheet to understand its proper orientation and pin configuration. Datasheets provide authoritative information directly from the manufacturer.

Breadboard Orientation Confusion

Solderless breadboards make prototyping convenient but introduce orientation challenges. The power rails running along the edges typically feature red and blue or black lines indicating positive and negative respectively, but these markings are only suggestions—you must ensure you connect your power supply correctly.

A common mistake involves assuming both sides of a breadboard have interconnected power rails. Many breadboards have separate power rails on each side, requiring jumper connections to link them. Additionally, some breadboards have power rails that split in the middle, requiring careful attention to ensure complete power distribution.

🎯 Advanced Polarity Concepts for Growing Skills

As your electronics skills develop, understanding more nuanced polarity concepts enables you to tackle increasingly sophisticated projects and troubleshoot complex circuits more effectively.

Bipolar vs. Unipolar Circuit Design

While beginner circuits typically use single polarity (unipolar) power supplies, many intermediate and advanced circuits require dual polarity (bipolar) supplies providing both positive and negative voltages relative to ground. Audio amplifiers, operational amplifier circuits, and many analog circuits benefit from or require bipolar supplies.

Understanding how to create and work with bipolar supplies opens new project possibilities. Virtual ground circuits offer one approach for creating bipolar-like operation from a single supply, useful in battery-powered applications where dual supplies prove impractical.

AC vs. DC Polarity Considerations

Alternating current circuits present different polarity considerations because the voltage and current direction constantly reverse. However, even AC circuits often include DC sections for control circuits, requiring careful attention to polarity in mixed-signal designs.

Bridge rectifiers convert AC to DC, creating polarity from a non-polarized input. Understanding this conversion process and the resulting polarity relationships helps when working with power supply designs and AC-powered devices.

💡 Polarity in Common Beginner Projects

Examining how polarity affects typical beginner projects provides practical context for theoretical knowledge. These examples demonstrate real-world applications of polarity principles.

LED Circuits and Current Direction

LED circuits perfectly illustrate polarity importance. An LED with reversed polarity simply won’t light, providing immediate feedback about orientation errors. The current-limiting resistor position doesn’t affect polarity requirements—it can go on either the anode or cathode side—but the LED itself must have its anode connected toward the positive supply.

Multi-LED circuits introduce additional complexity, particularly regarding series versus parallel configuration. In series LED strings, current flows through each LED in sequence, so all must face the same direction. Parallel LED arrangements allow independent current paths but require current-limiting resistors for each LED or branch.

Motor Control Circuit Polarity

DC motors demonstrate polarity effects dramatically—reversing polarity reverses rotation direction. This principle underlies H-bridge circuits that enable electronic motor direction control. Understanding motor polarity helps when building robot projects or other mechanical control applications.

Small motors can withstand brief polarity reversals, but larger motors or those with electronic speed controllers may suffer damage from reversed connections. Always verify polarity before connecting motors to control circuits, especially when using expensive or specialized motors.

Sensor Circuit Orientation

Many sensors, including temperature sensors, light-dependent resistors, and various digital sensors, have specific polarity requirements. Sensor datasheets clearly specify pin configurations, but physical packages may have subtle markings indicating proper orientation.

Digital sensors using I²C or SPI communication protocols are particularly sensitive to polarity errors because reversed power connections can damage internal circuitry instantly. Double-checking sensor orientation before applying power prevents costly replacements and project delays.

📊 Building a Polarity Reference System

Creating personal reference materials helps reinforce polarity knowledge and provides quick consultation resources during project building. A well-organized reference system reduces errors and speeds up your workflow.

Consider maintaining a physical or digital notebook documenting common components you use, their polarity requirements, and marking conventions. Include photographs or drawings showing proper orientation for components you use frequently. This personalized reference becomes increasingly valuable as your component inventory grows.

Label your component storage containers with polarity information and key specifications. When you grab an electrolytic capacitor from storage, having the polarity marking convention noted on the container saves time and reduces errors. Small investments in organization yield substantial returns in efficiency and reliability.

🔍 Troubleshooting Polarity-Related Issues

When circuits malfunction, polarity errors rank among the most common causes, especially in beginner projects. Developing systematic troubleshooting approaches quickly identifies and resolves these issues.

Start by verifying power supply polarity at multiple points in your circuit using a multimeter. Confirm voltage is present where expected and measure actual values against design specifications. If voltage is absent or incorrect, trace backward from that point toward the supply, checking connections and component orientation.

For circuits that power up but don’t function correctly, systematically verify each polarized component’s orientation. Remove power before checking component polarity to prevent measurement errors or additional damage. Compare your physical circuit against your schematic, checking one component at a time rather than trying to verify everything simultaneously.

If you suspect a component was damaged by incorrect polarity, remove it from the circuit and test it independently. Electrolytic capacitors can be tested for shorts using a multimeter’s continuity function. Diodes and LEDs can be tested using the diode test mode. ICs and transistors often require replacement if polarity damage occurred, though testing other circuit sections first may reveal the damaged component wasn’t critical to that particular malfunction.

🚀 Advancing Beyond Polarity Basics

Mastering polarity fundamentals provides the foundation for exploring more advanced electronics concepts. As comfort with basic polarity grows, you naturally encounter situations requiring deeper understanding of circuit behavior and component characteristics.

Consider exploring programmable electronics platforms that teach polarity principles through hands-on experimentation. Arduino and similar microcontroller boards offer excellent learning opportunities, requiring careful attention to component polarity while providing immediate feedback through program functionality.

The journey from beginner to intermediate electronics enthusiast involves gradually increasing circuit complexity while maintaining fundamental principles like proper polarity orientation. Each successful project reinforces good habits and builds confidence for tackling more challenging designs.

Remember that even experienced engineers occasionally make polarity errors—the difference lies in their systematic verification processes and quick identification when problems occur. Developing these professional habits early accelerates your learning and prevents frustration as projects become more complex.

Polarity mastery isn’t about never making mistakes; it’s about understanding principles deeply enough to predict component behavior, verify designs before applying power, and troubleshoot efficiently when problems arise. This knowledge forms an essential part of your electronics foundation, supporting everything you build throughout your electronics journey.

Toni Santos is an educational technology designer and curriculum developer specializing in the design of accessible electronics systems, block-based programming environments, and the creative frameworks that bring robotics into classroom settings. Through an interdisciplinary and hands-on approach, Toni explores how learners build foundational logic, experiment with safe circuits, and discover engineering through playful, structured creation. His work is grounded in a fascination with learning not only as skill acquisition, but as a journey of creative problem-solving. From classroom-safe circuit design to modular robotics and visual coding languages, Toni develops the educational and technical tools through which students engage confidently with automation and computational thinking. With a background in instructional design and educational electronics, Toni blends pedagogical insight with technical development to reveal how circuitry and logic become accessible, engaging, and meaningful for young learners. As the creative mind behind montrivas, Toni curates lesson frameworks, block-based coding systems, and robot-centered activities that empower educators to introduce automation, logic, and safe electronics into every classroom. His work is a tribute to: The foundational reasoning of Automation Logic Basics The secure learning of Classroom-Safe Circuitry The imaginative engineering of Creative Robotics for Education The accessible coding approach of Programming by Blocks Whether you're an educator, curriculum designer, or curious builder of hands-on learning experiences, Toni invites you to explore the accessible foundations of robotics education — one block, one circuit, one lesson at a time.